Tractor clutches are a critical component of the tractor’s transmission system, which allows for the smooth engagement and disengagement of the engine power to the transmission. There are different types of tractor clutches, each with its unique design and performance characteristics.

Types of tractor clutches

.jpg)

Single-disc clutch

This type of clutch is the most common and simplest design of tractor clutch. It consists of a single friction disc that is pressed against a flywheel by a pressure plate to transmit power to the transmission.

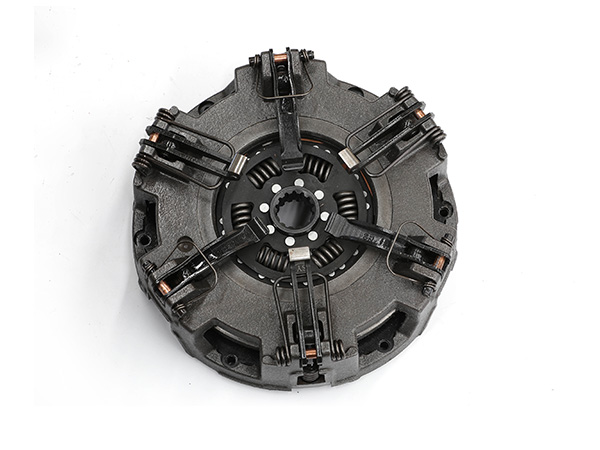

Dual-disc clutch

This type of clutch consists of two friction discs and a pressure plate. The discs are designed to alternate to transfer the power smoothly to the transmission.

Cone clutch

This type of clutch uses a conical shape for both the clutch plates. The cone clutch operates by sliding the cones together, allowing the power to be transmitted to the transmission.

Mechanical clutch

This type of clutch is operated manually by the driver using a foot pedal or lever. It uses a cable or linkage to connect the clutch pedal to the clutch mechanism.

Hydraulic clutch

This type of clutch is operated hydraulically using hydraulic fluid. It is similar to a mechanical clutch, but instead of a cable or linkage, it uses a hydraulic cylinder to engage and disengage the clutch.

Power-shift clutch

This type of clutch is used in tractors with power-shift transmission. It is a type of hydraulic clutch that allows for smooth shifting of gears without the need for manual clutch operation.

The choice of clutch type depends on the specific needs and requirements of the tractor’s application, such as the power output, load capacity, and the desired level of control and efficiency.