A tractor clutch plate, also known as a clutch disc, is a critical component of the clutch system in a tractor. The clutch plate is located between the tractor’s engine flywheel and the clutch pressure plate. Its primary function is to engage and disengage power transmission between the engine and the transmission system, allowing the tractor to change gears or come to a complete stop without stalling the engine.

The size of a tractor clutch plate can vary depending on the make and model of the tractor. Clutch plates are designed to fit specific tractor models, and different tractors may have different clutch plate sizes.

To determine the size of a tractor clutch plate, it is necessary to refer to the tractor’s specifications or consult the tractor’s manufacturer or authorized dealer. They can provide accurate information regarding the size, dimensions, and compatibility of the clutch plate for a specific tractor model.

It’s important to note that tractor clutch plates are available in various diameters, thicknesses, and spline configurations to match the tractor’s clutch system. Using the correct size and type of clutch plate is crucial for proper functioning and compatibility with the tractor’s transmission system.

Here are some key points about tractor clutch plates:

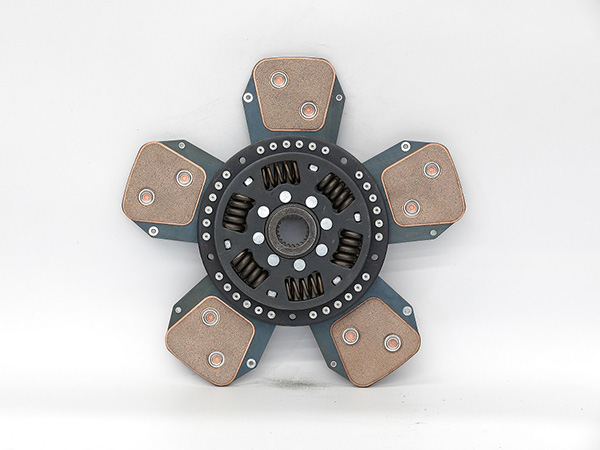

Construction: A tractor clutch plate consists of a friction material, typically made of a high-friction material such as organic, ceramic, or metallic compounds. The friction material is bonded or riveted to a metal disc, providing the necessary grip and friction to transmit engine power to the transmission when engaged.

Engagement and Disengagement: When the clutch pedal is pressed, the clutch release mechanism disengages the clutch plate from the engine flywheel, interrupting the power flow and allowing gear changes or stops. Releasing the clutch pedal re-engages the clutch plate, allowing power transfer between the engine and transmission to resume.

Wear and Replacement: The friction material on the clutch plate is subject to wear over time due to the high forces and friction involved. Regular use, improper clutch operation, or excessive slipping can accelerate wear. Eventually, the clutch plate may need to be replaced when the friction material reaches a certain thickness, significantly affecting performance.

Maintenance and Adjustment: Proper maintenance of the clutch system is crucial to ensure optimal performance and longevity. Regular inspections, lubrication, and adjustment of the clutch linkage and pedal play are necessary. Additionally, maintaining the proper clutch pedal freeplay and avoiding excessive slipping during operation can help prolong the life of the clutch plate.

Compatibility: When replacing a tractor clutch plate, it is important to ensure compatibility with the tractor’s make, model, and specific clutch assembly. Clutch plates are available in various sizes, friction materials, and designs, so it is essential to consult the tractor manufacturer’s specifications or seek professional advice to select the correct clutch plate for replacement.

It’s worth noting that the design and specific features of tractor clutch plates can vary depending on the tractor model, manufacturer, and application. Consulting the tractor’s owner’s manual or seeking assistance from a qualified mechanic or tractor parts supplier can provide detailed information about the appropriate clutch plate for a specific tractor.