Regular lubrication of the clutch After the clutch works for a period of time, in order to reduce friction and damage, it must be filled with butter for lubrication. Usually, the front bearing and release bearing of the clutch should be filled with butter every 10 to 20 hours of operation of the tractor. When filling, if you use the oil gun to hit the oil for 3 to 5 times, the friction lining will slip if too much butter is stained. The models included in the common tractors at this stage use closed release bearings. The locomotive does not need to be filled with butter during normal operation. After 200 to 300 hours of operation, the bearings are impregnated with butter. Remove the release bearing, clean it with diesel oil, and then infiltrate the melted butter to fill the bearing with butter. After the water cools and solidifies, it can be removed and re-installed.

Precautions for tractor clutch

- Start to check whether the speed control operating handle is in the neutral position, whether the parking brake is in the braking position, and whether the power take-off handle is in the separation position, otherwise it will lead to a safety production accident.

- The tractor should observe whether the water temperature gauge and oil pressure gauge are normal during the application, otherwise it will cause abnormality in the vehicle and affect the application.

- When the tractor is transporting, the left and right brake pedals are chained together to prevent uncontrollable automatic steering during braking and lead to production safety accidents.

- The driver is forbidden to put his foot on the clutch pedal and brake pedal during the work of the tractor, otherwise it will cause the initial damage of the clutch and brake disc, which will affect the application.

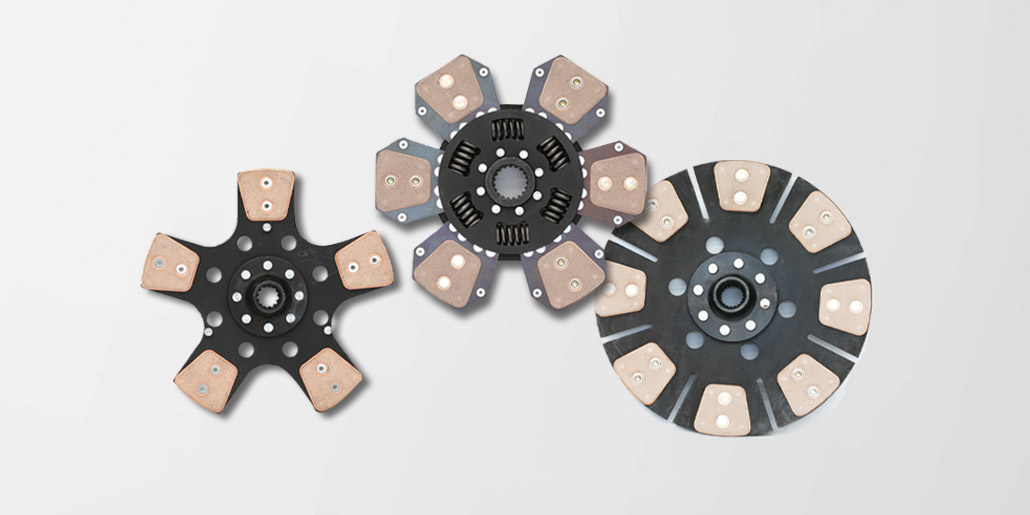

Luoyang Shengyuan Clutch Co., Ltd.* is committed to the research and development and production of tractor clutch assemblies and clutch friction plates. It has a complete set of clutch production equipment, as well as the advanced tractor clutch assembly comprehensive testing and testing machine and durability test in the domestic clutch industry. The machine and disc spring testing machine effectively guarantees the comprehensive performance of the clutch by controlling the whole process of parts, assembly assembly and comprehensive testing.