The friction disc material used in clutches plays a crucial role in the performance, durability, and reliability of the clutch system. Various materials are used for friction discs, each offering different properties and suitability for specific applications.

Clutch Friction Disc Materials

Organic: Organic friction disc materials are composed of non-metallic materials such as cellulose, aramid fibers, and other organic compounds bonded together with a resin. Organic friction discs offer smooth engagement, good heat dissipation, and low noise levels. They are suitable for light to moderate-duty applications such as passenger vehicles and light trucks. However, they may wear more quickly under heavy loads or aggressive driving conditions.

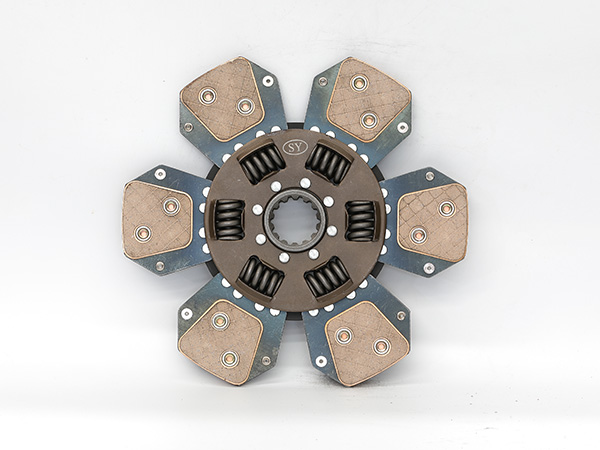

Feramic (Fiber Ceramic): Feramic friction discs combine organic fibers with ceramic materials to improve heat resistance and durability. Feramic materials offer higher torque capacity, improved wear resistance, and better performance under high-temperature conditions compared to organic materials. They are commonly used in performance vehicles, racing applications, and heavy-duty trucks where higher torque and temperature capabilities are required.

Kevlar: Kevlar is a high-strength synthetic fiber known for its exceptional tensile strength, heat resistance, and durability. Friction discs made with Kevlar fibers offer excellent performance under high temperatures and heavy loads. Kevlar-based friction materials are often used in racing clutches and high-performance vehicles where extreme operating conditions are encountered.

Carbon Composite: Carbon composite friction discs consist of carbon fibers embedded in a resin matrix. Carbon composite materials offer high heat resistance, low wear rates, and consistent friction performance over a wide range of operating conditions. They are commonly used in racing clutches, high-performance vehicles, and heavy-duty applications where reliability and durability are critical.

Ceramic: Ceramic friction discs utilize ceramic materials to provide exceptional heat resistance, wear resistance, and durability. Ceramic materials offer superior performance under high temperatures and heavy loads, making them ideal for racing applications, high-performance vehicles, and heavy-duty trucks.

The choice of friction disc material depends on factors such as the application, operating conditions, vehicle type, and performance requirements. Manufacturers may also use proprietary formulations and manufacturing processes to tailor friction disc materials to specific applications and performance objectives.

-80x80.jpg)