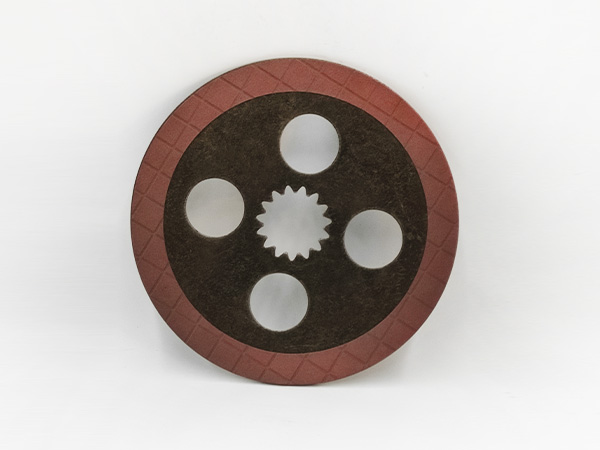

The friction disc is the main component of the tractor clutch, and the physical properties and mechanical properties of its working surface material directly affect the working performance of the clutch. So what are the materials of the clutch friction disc?

The effect of clutch friction disc

1. Transmission of rotational torque

The engine flywheel is the active part of the clutch, and the driven disc and the driven hub containing the friction plate are connected with the driven shaft by the rolling spline shaft. If the spring is clamped, the driven disc is clamped on the end surface of the flywheel of the water pump.

2. Engine torque

That is, it is transmitted to the driven disk by the friction effect between the water pump flywheel and the surface of the driven disk, and then sent to the driving wheel through the driven shaft and a series of components in the transmission system. The greater the clamping force of the spring, the greater the torque that the clutch can transmit.

Material of clutch friction disc

Friction parts are the key components of friction clutches, and the chemical properties and physical properties of the surface materials during their work immediately endanger the working characteristics of the clutch.

Common friction surface materials include powder metallurgy materials, asbestos-based materials, and rock-based materials.

1. Powder metallurgy materials

The surface allowable temperature, allowable working pressure, friction index at high temperature and service life are all high.

2. Copper base powder is not metallurgical

The key is to wet test the friction surface. The friction index and allowable working pressure of iron-based powder unmetallurgical materials are higher than those of copper-based materials, but the wear resistance is lower, and it is mostly used to dry test the friction surface.

3. Asbestos-based materials

It is made of asbestos plus binder and filler, and the soil is on a steel or iron base plate, and the allowable operating temperature is low.

4. Paper-based materials

It is made of asbestos, fibrous materials or compounds of the two to complement each other, and then bonded by epoxy resin after adding fillers. This type of material has a porous structure, good friction characteristics, similar dynamic and static friction indices, and low cost.

The main requirements for the material are: the coefficient of friction is large and stable, and the coefficient of dynamic friction should be as close to the coefficient of static friction as possible; high strength, can withstand impact, not easy to crack and peel at high speed; wear resistance, high temperature resistance, corrosion resistance and thermal conductivity. Small deformation; long-term standing should not cause adhesion. In addition, long service life, easy processing and low cost are also required.

-80x80.jpg)